1 2012 dimensions in mm zd 3. The components can be configured into a system quickly and economically.

Rack And Pinion Stamp Gear 3 Industrial Design Sketch Design Sketch Solid Works

Rack And Pinion Stamp Gear 3 Industrial Design Sketch Design Sketch Solid Works

Each center drive pinion engages a straight line rack which causes the bridge to move.

Rack and pinion gear design pdf. Rack and pinion housing. Atlanta b servo worm gear unit. Rack and pinion gear design free download as powerpoint presentation ppt pdf file pdf text file txt or view presentation slides online.

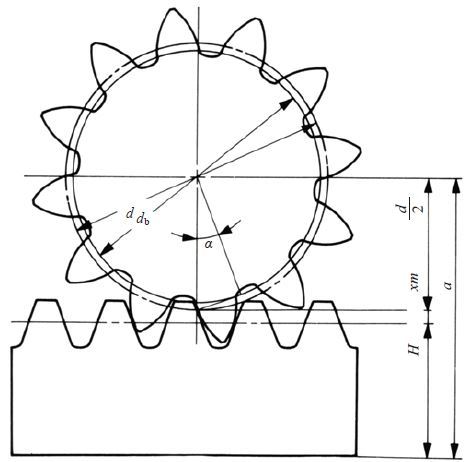

Machine design gear design rack and pinion design. If the mating gear has more teeth than the pinion that is. Because the pinion drive gears are supposed to be in the exact centers of the sector circles the pinion gear moves back and forth along a straight line.

Modular system purchase the rack and pinion drive as individual components as a gearbox with matching pinion and rack. Hp and e servo worm gear unit bg bevel gear unit 1 5 for unpreloaded bearings on the output shaft e g. This permits the pitch line of pinion gear teeth to be in line with the pitch line of the rack.

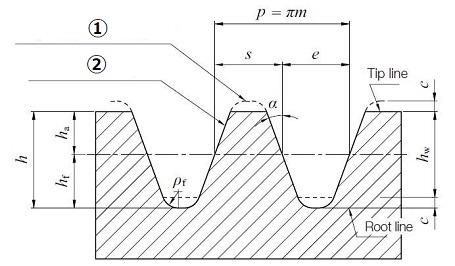

You benefit from minimum assembly work and fast start up. The smallest number of teeth on a spur pinion and gear one to one gear ratio which can exist without interference is np. The number of teeth for spur gears is given by where k 1f fll1 for full d tht th08f tbt th d ldepth teeth 0 8 for stub teeth and φ pressure angle.

When you turn the steering wheel the gear spins moving the rack. Ss en9 material has been used to manufacture pinion with module of 1 5 and pitch circle diameter of 18mm and for rack ss410 material has been used with length of 340mm. A typical case would involve the design of the gearing for a hoist to raise a certain weight w ata.

A gear rack has straight teeth cut into one surface of a square or round section of rod and operates with a pinion which is a small cylindrical gear meshing with the gear rack. The tie rod at each end of the rack connects to the steering arm on the spindle. Rack and pinion transmission has achieved inside.

Rack and pinion drive with pinion pre mounted on the output shaft of the gearbox. Generally gear rack and pinion are collectively called rack and pinion. Atlanta servo catalog 2013 pdf author.

Rack and pinion drive calculation and selection. The results of the design shows that weight of new rack and pinion gearbox is 20 less than the oem rpg with nearly 40 reduction in the cost achieving the desired steering ratio. Basic rack and.

Where np and ng number of teeth in pinion and gear. Rack and pinion steering one of the most common application is the rack and pinion steering. Np and ng revolutions per minute rpm of pi nion and gear respectively the ratio of speed to torque is of the utmost importance in the design of gear teeth to transmitand use the power.

It is the most common type of steering on cars small trucks and suvs. Gear racks are utilized to convert rotating movement into linear motion. Rack and pinion has been designed to get accurate motion transmission from the bevel gear to pinion.

Me 340 Modeling Of A Rack And Pinion System Youtube

Me 340 Modeling Of A Rack And Pinion System Youtube

Robotic Mechanisms All Types Of Gears 51034 Robotpark Academy Gears Bevel Gear Pinion Gear

Robotic Mechanisms All Types Of Gears 51034 Robotpark Academy Gears Bevel Gear Pinion Gear

How To Building Wooden Rack And Pinion Gear Pdf Download Plans Ca Wooden Gears Simple Machines Gears

How To Building Wooden Rack And Pinion Gear Pdf Download Plans Ca Wooden Gears Simple Machines Gears

Flywheel Wood Splitter Components Wood Splitter Log Splitter Flywheel

Flywheel Wood Splitter Components Wood Splitter Log Splitter Flywheel

Calculation Of Gear Dimensions Khk Gears

Calculation Of Gear Dimensions Khk Gears

Https Www Hpcgears Com Pdf C33 Rack Pinion Pdf

Involute Gear Profile Khk Gears

Involute Gear Profile Khk Gears