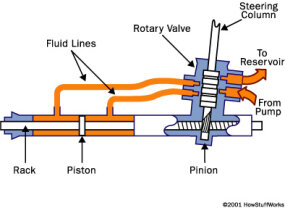

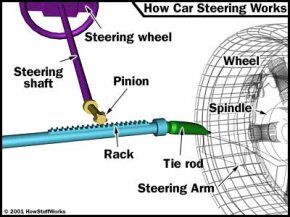

The recirculating-ball steering gear contains a worm gear. A rack and pinion are used when converting rotational movement to linear motion or vice versa.

Variable Pitch Rack And Pinion System Page 1 Line 17qq Com

Variable Pitch Rack And Pinion System Page 1 Line 17qq Com

A method for rack cutting on a variable ratio rack pinion steering gear characterized by being composed of disposing a cutter of standardized tooth pitches with respect to the axis of a rack bar to form a given helical angle disposing a cutter of standardized tooth pitches with respect to the axis of a rack bar to form a given helical angle obtaining a variable ratio having a given inclined angle and virtual path of rack rotation with the racktravel being such that said rack.

Variable pitch rack and pinion diagram. For example the reference pitch of m 3 rack is 9425 mm 3 x π. Kathireshan Rohit G Prasad. A variable-pitch region is interposed between the middle fixed pitch region.

When using a rack and a pinion in a linear motion application the fact that the pitch is not an integral number presents a difficulty in accurate positioning. Gear Rack and Pinion creation of linear motion. The first part is a block of metal with a threaded hole in it.

Pinion carriers mounted onto flex-plates have found to be the best arrangement. A bar shaped gear with an infinite flat surface radius of a cylindrical gear is called a rack and a meshed spur gear is called a pinion. Rack tooth surface has to be adjusted in order to achieve variable ratio.

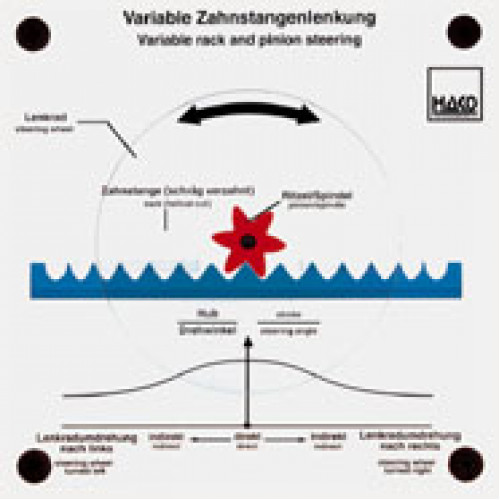

Some cars have variable-ratio steering which uses a rack-and-pinion gearset that has a different tooth pitch number of teeth per inch in the center than it has on the outside. This has been rejected as undesirably fast steering. Has a larger pitch radius than standard by the amount xm.

This problem is solved by CP racks and pinions where one rotation of a pinion moves it precisely 50 100 150. DESIGN AND FABRICATION OF VARIABLE RACK AND PINION STEERING GEOMETRY R. Asked by Wiki User.

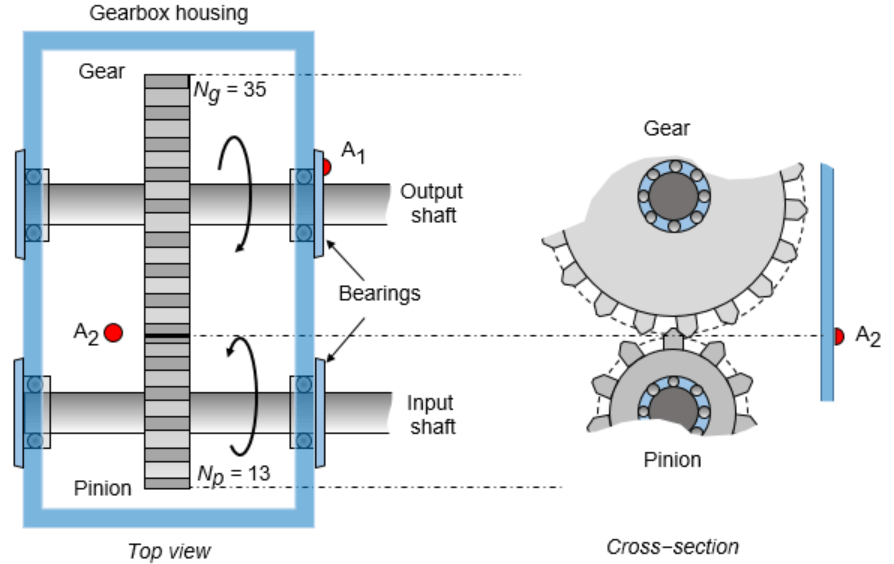

Table presents the calculation of a meshed profile shifted spur gear and rack. Such a gear is limited to about 18 turns of the steering wheel to steer the vehicle from lock-to-lock. P πm Linear Pitch p Normally a 20o Pressure Angle a.

A variable ratio rack and pinion steering mechanism having an axially movable rack meshing with a helical pinion the axis of whiCh makes an angle to the axis of the rack the rack being characterized by having a group of teeth at its center whose form is different at every section across the width of the rack and having other teeth each side of said group having a constant form at every section across the width of the rack said group of teeth providing a varying effective pitch. Rack and pinion systems are a. An attempt to remedy this has been made by introducing a.

This rack and pinion steering system uses a different number of teeth per cm tooth pitch in the centre than at the ends. Why is a variable pitch rack and pinion system sometimes used. As a general rule rack lengths below 255 mm should use 3 clamps per rack 255 mm to 375 mm should use 4 clamps per rack and rack lengths above 375 mm should use 5 or 6 clamps per rack.

Depending on the pitch of the threads on the rack and pinion. Its a variable pitch rack. A variable-pitch racked bar has a row of rack teeth with a middle fixed pitch region and two end fixed pitch regions.

The variable pitch part means that where a normal rack is flat this one is curved to change the way it feels and acts when the driver turns the wheel. The result is the steering is more sensitive when it is turned towards lock than when it is close to its central position making the. CONTENTS MODULAR RACK PINION SYSTEM The standard range is available in modules M 10 to 100 Diametral pitch P 254 to 254 with lengths up to 3 meters allowing loads from.

The linkage that turns the wheels is slightly different than on a rack-and-pinion system. If the correction. For not-engineers its the part of a rack and pinion steering system that turns the rotation of the pinion gear into linear motion to turn the wheels.

With rack and pinion steering the rotation of the pinion causes linear motion of the rack which turns the vehicles wheels left or right. Also the pitch line of the rack has shifted outward by the amount xm. One method which has been tried is to provide a pinion with variable pitch radius and a rack with varying height teeth to match.

A spur rack has a planar pitch surface and straight teeth that are at right angles to the direction of motion. You can image the gear in two parts. Unfortunately none of existing engineering books provide algorithm for mathematical calculation of the vr-rack tooth surface.

Variable ratio rack and pinion set is commonly used for steering systems on automobiles. This makes the car respond quickly when starting a turn the rack is near the center and also reduces effort near the wheels turning limits. Some cars use variable ratio steering.

The standard pitch circle is the circle which intersects the involute at the point where the pressure angle is equal to the profile angle of the basic rack. Pinion Pitch Circle module d mz Physical diameter of the gear d Linear distance between the teeth of the rack. Cannot be used with angular measuring rack.

Solved In The Motorized Rack And Pinion System In A Milling Machine The Pini Solutioninn

Solved In The Motorized Rack And Pinion System In A Milling Machine The Pini Solutioninn

Variable Pitch Rack And Pinion System Page 1 Line 17qq Com

Variable Pitch Rack And Pinion System Page 1 Line 17qq Com

Https Www Jstor Org Stable Pdf 44730902 Pdf

6 Speed Gearbox Radio Control Planes Mechanical Engineering Gears

6 Speed Gearbox Radio Control Planes Mechanical Engineering Gears

Flapping Wing Mechanism Reciprocating Gear Mechanism Diy Wings Gears Diy Science

Flapping Wing Mechanism Reciprocating Gear Mechanism Diy Wings Gears Diy Science

Me 340 Modeling Of A Rack And Pinion System Youtube

Me 340 Modeling Of A Rack And Pinion System Youtube

Rack And Pinion Steering How Car Steering Works Howstuffworks

Rack And Pinion Steering How Car Steering Works Howstuffworks

Design Of Reciprocating Rack And Pinion Mechanism Dual Working Mechanism Semantic Scholar

Design Of Reciprocating Rack And Pinion Mechanism Dual Working Mechanism Semantic Scholar

Variable Rack And Pinion Steering 810000232 Technolab Sa

Variable Rack And Pinion Steering 810000232 Technolab Sa

Cp Racks Pinions Technical Information

Cp Racks Pinions Technical Information

Https Www Jstor Org Stable Pdf 44720834 Pdf

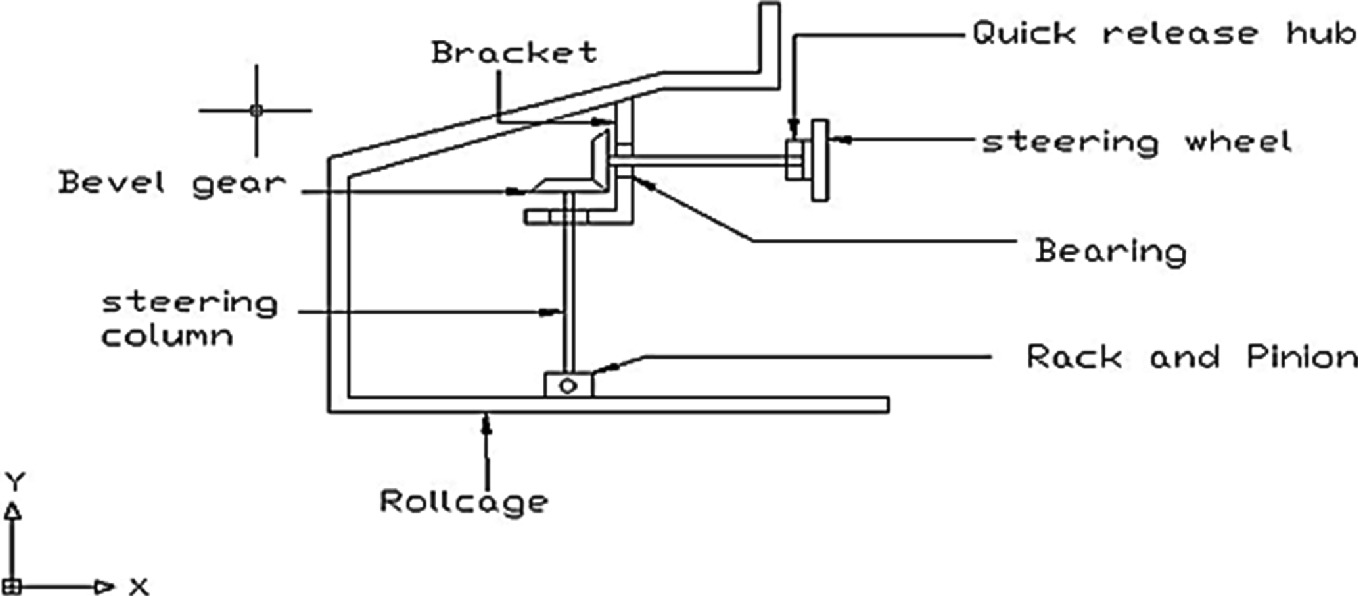

Design And Development Of Steering System For Formula Styled Vehicle Springerlink

Design And Development Of Steering System For Formula Styled Vehicle Springerlink

Design Of Reciprocating Rack And Pinion Mechanism Dual Working Mechanism Semantic Scholar

Design Of Reciprocating Rack And Pinion Mechanism Dual Working Mechanism Semantic Scholar

Vibration Analysis Of Rotating Machinery Matlab Simulink

Vibration Analysis Of Rotating Machinery Matlab Simulink

Variable Pitch Rack And Pinion System Page 1 Line 17qq Com

Variable Pitch Rack And Pinion System Page 1 Line 17qq Com

Build Powerful Linear Actuators From Windshield Wiper Motors And Car Jacks Youtube Linear Actuator Car Wiper Car Jack

Build Powerful Linear Actuators From Windshield Wiper Motors And Car Jacks Youtube Linear Actuator Car Wiper Car Jack

Planetary Gear Reduction Drive Psd Google Search

Planetary Gear Reduction Drive Psd Google Search

Figure 4 From Design Of Reciprocating Rack And Pinion Mechanism Dual Working Mechanism Semantic Scholar

Figure 4 From Design Of Reciprocating Rack And Pinion Mechanism Dual Working Mechanism Semantic Scholar

Rack And Pinion Steering How Car Steering Works Howstuffworks

Rack And Pinion Steering How Car Steering Works Howstuffworks